Thermal Separation Processes and (Bio-)Refinery

The ability to separate mixtures of substances due to their different boiling points has been known about for a long time: more than two thousand years ago, Aristotle described how seawater can be made drinkable using distillation.

That method is still widely used today but is increasingly being replaced by energy-saving membrane processes. These thermal separation processes are used especially in the petroleum and process industries for solvent extraction and recovery. In relation to renewable resources, they are particularly important for reliable purification in biorefineries.

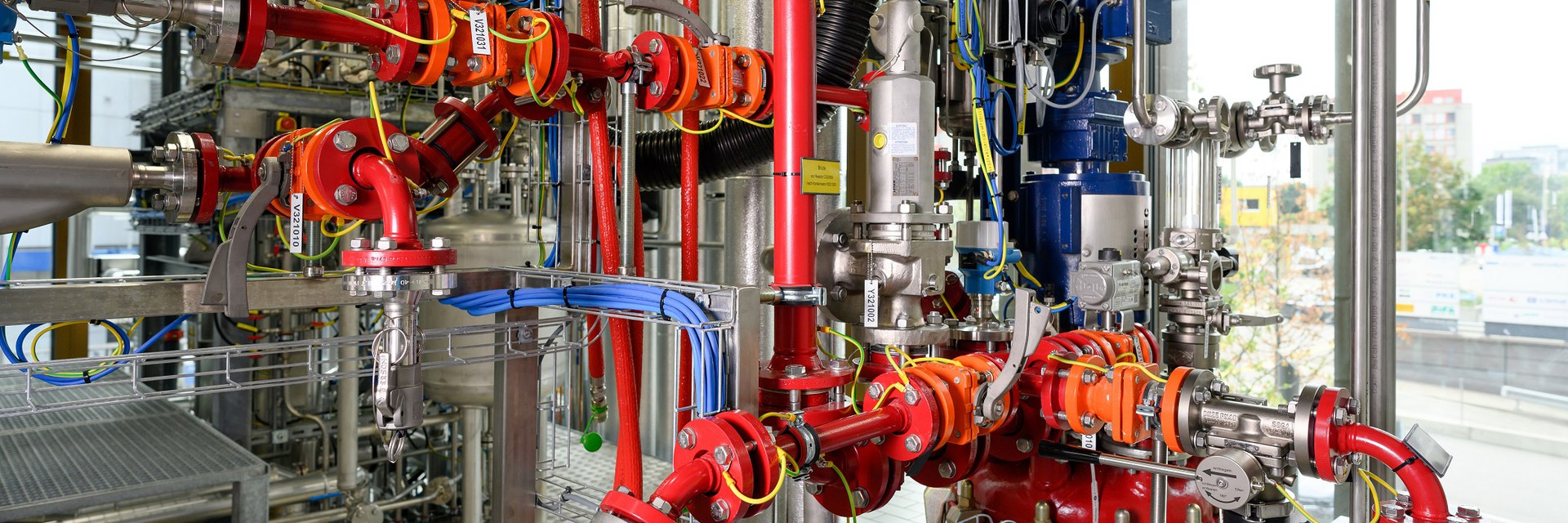

Thermal separation processes take up a large part of the PTC: three floors are occupied by a technical rectification column, falling-film and thin-layer evaporators, a filter slide and tray dryer, and an innovative pervaporation/vapour permeation system. They are located in an Ex-zone (II/T3) and are equipped with a process control system and extensive in-line measuring technology. All separation processes can also be combined with each other and/or with a 100 litre steel enamel reactor or a 100 litre bioreactor (fermenter). An external tank storage facility provides supply and disposal services for these process chains, so that continuous operation over several days is possible.

For example a bioethanol process can be mapped just as completely, from fermentation to the production of anhydrous, high-purity bioethanol, as environment-friendly solvent recycling.

All plants are structurally equivalent to comparable large-scale plants: the samples produced are representative and the scale-up of test results to production scale is valid.

FHNW students receive technically advanced, application-oriented undergraduate and postgraduate training at the PTC.

Infrastructure

- 100 litre reactor, steel/enamel (-1/3 bar)

- 100 litre fermenter, steel/enamel (-1/3 bar)

- Rectification column (DN 100, -1/3 bar)

- Falling film evaporator (1 m2)

- Thin film evaporators (0.2 m2 and 0.07 m2)

- Short path evaporator (0.04 m2)

- Pervaporation / vapour permeation (10-20 l/h), polymer and ceramic membrane

- Filter dryer (100 l, Hastelloy)

- Product grinding, filling and packaging

- Ex-zone (II/T3)

- Tank storage (Ex-zone) for solvent handling (continuous operation)

- Cooling rail +2...8°C

- Heating steam 6 bar