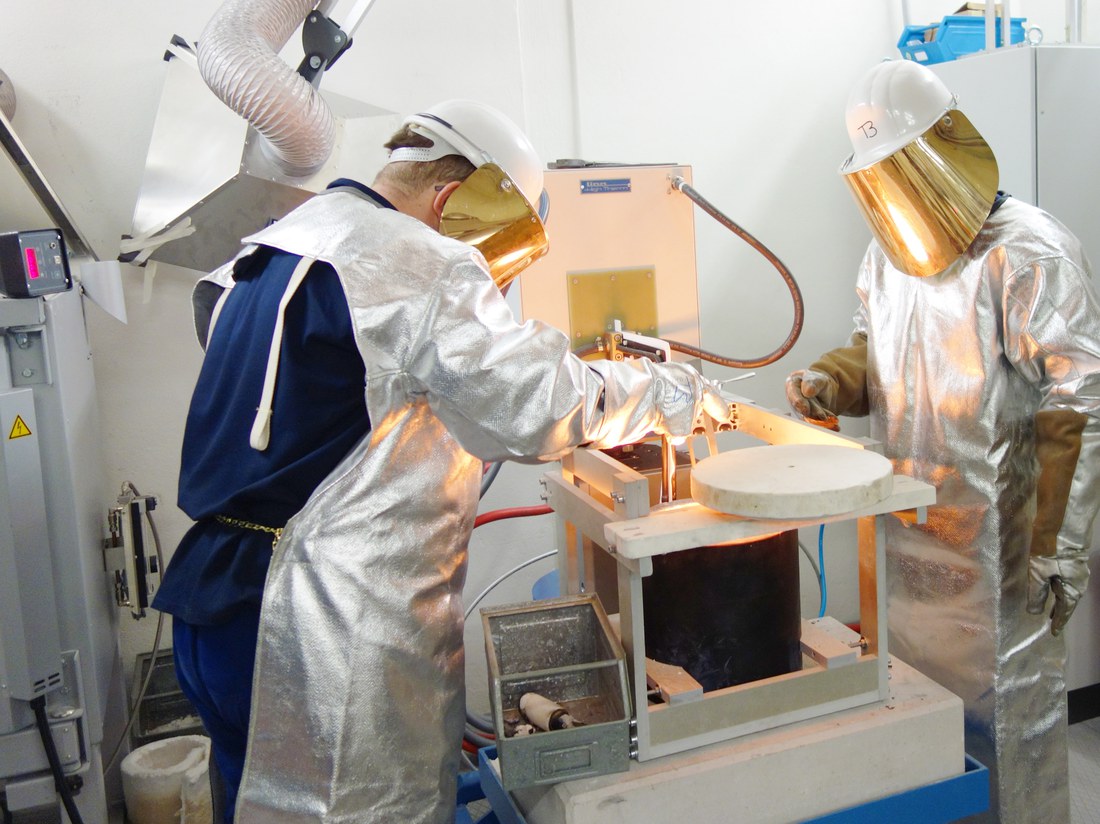

Casting laboratory

Various melts of up to four litres in volume can be created in the induction-heated crucible furnace with lift coil mechanism. The furnace has a heating capacity of 50kW.

Using a self-designed and highly flexible casting facility it is possible to cast temporary and permanent moulds under pressure or negative pressure. It is possible to cast under gravity using the top pouring method or with low pressure using bottom pouring.

A moulding sand mixer with a volume of 60 litres enables sand moulds to be made with organic and inorganic binder systems.

Various thermal treatment furnaces can be used for further processing of the cast parts.

Share this page: