They see me rollin’

As you may expect from the title, we want to give you an update about our drivetrain.

If you follow us on Instagram, you may have seen our posts and stories regarding the drivetrain. Nevertheless, we want to show you the whole process of designing and manufacturing the drivetrain.

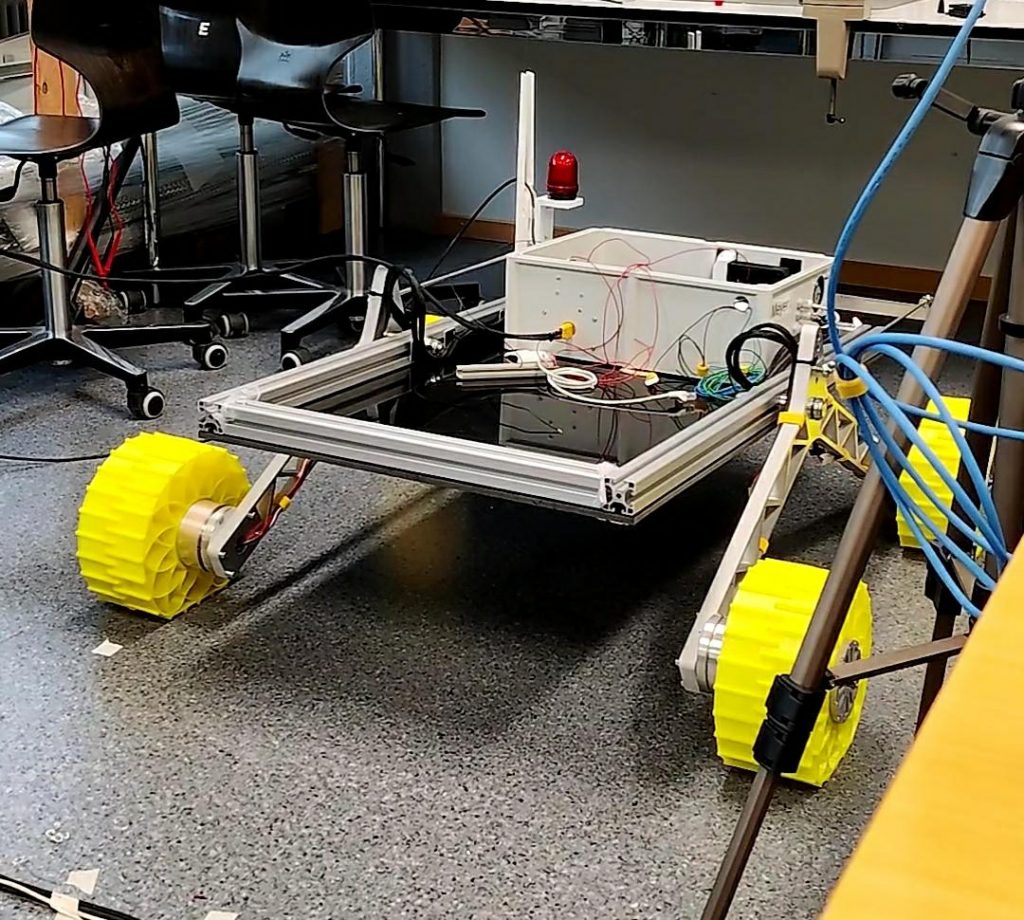

Last semester, when we started the project, we had no idea how to design a drivetrain with a suspension. Especially for an offroad vehicle like a Rover. So of course our first step was research. While researching this topic we realized that the most used suspension for rovers is a rocker-bogie-suspension. This was the reason why we chose this system. Our basic design consists of just a rocker and a deflection mechanism resulting in a simple drivetrain, suitable for testing and competition. Our tires are 3D-printed with a flexible filament. A big thank you to our sponsor Fabru gmbh for providing the flexible filament.

Our second objective for the design was to design every motor attachment differently so that we can test different designs with one prototype. Over Christmas, we finalized our design and in January we sent our parts to the workshop for manufacturing.

While we were waiting for the parts to be finished, we enjoyed our hard-deserved break and started dreaming about how our Rover will start driving in no time.

But after four weeks, when the parts finally arrived, the harsh reality kicked in. A few parts were manufactured wrong.

For example, some parts were manufactured with the wrong threads or even with the wrong material (aluminum instead of POM). So we had to send the wrong manufactured parts back to the workshop and wait another three weeks. We used this time to finish developing our robotic arm and ordering it from the workshop. We will inform you about the arm in a different post. We even found time to test print our wheels. Luckily this time the parts were right so we could assemble the Drivetrain and attach it to the prototype. However, another problem appeared. We had printing problems with the tires. The filament absorbed too much water during the printing. So we had to put the filament in a drying box during the printing.

With this solution, we managed to print all four wheels and attach them to the rover. And so, on the 30. of march our Rover drove for the first time.

Jan, Group Leader Drivetrain

Comments

No comment posted about They see me rollin’