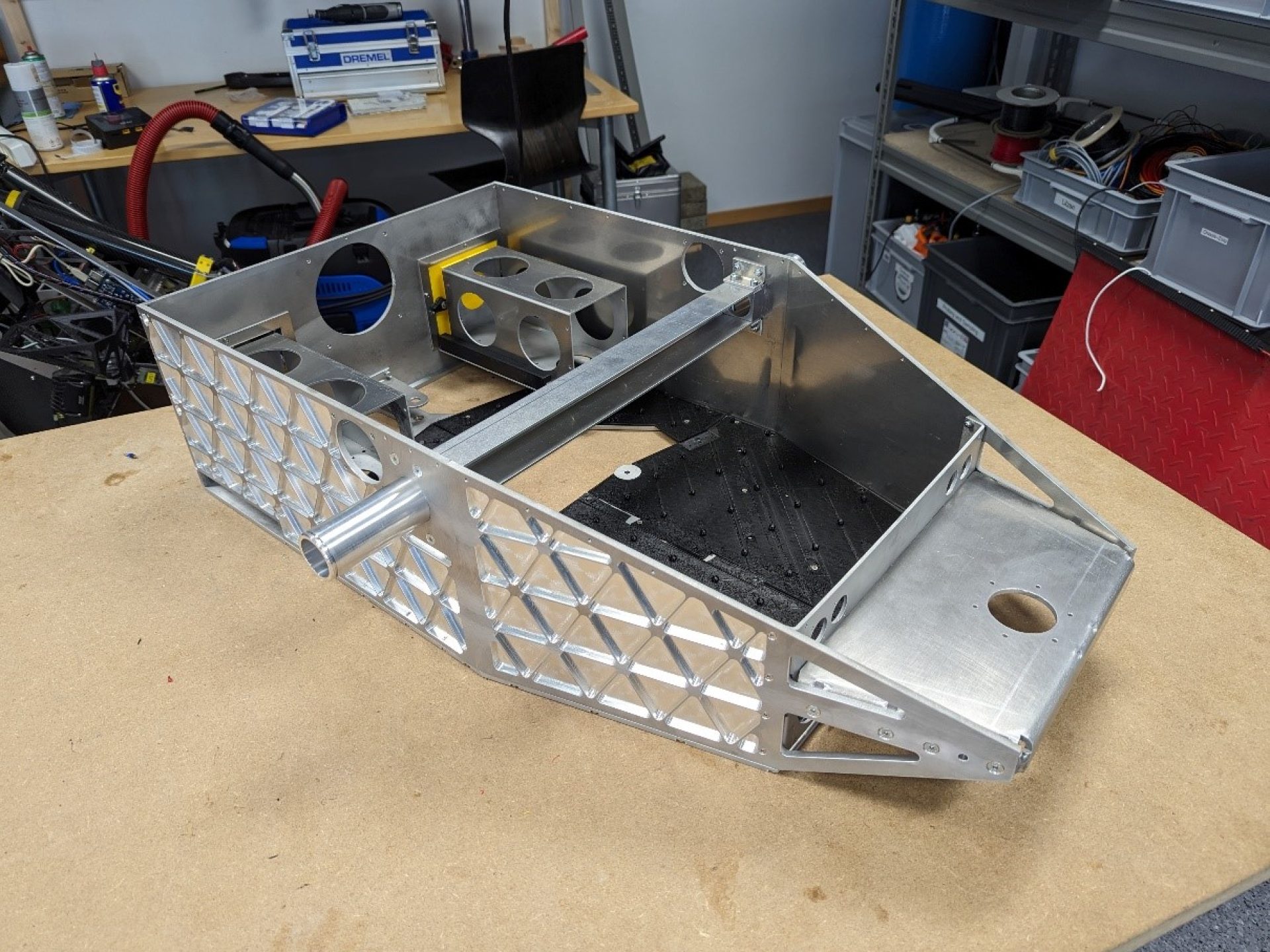

Chassis V3.0

Looking ahead to the ERC24, the FHNW Rover Team has planned many innovations and revisions, which also place new demands on the rover’s chassis. Some of these requirements include more space inside the chassis, a new mounting point for the upcoming drivetrain and the integration of a system that allows for the batteries to be hot-swapped.As the central component of the rover, the chassis must withstand numerous forces. In order to make the chassis to be as light as possible, it is important to plan the absorption of these forces well. Wherever possible, an attempt was made to achieve 2D state of stress, i.e. no forces act vertically on the walls. As a result, the side walls can absorb a large proportion of all forces despite being so thin. To withstand the moment generated by the drivetrain, a U-profile runs right through the chassis. This reinforces the overall structure and…