The evolution of the DriveTrain

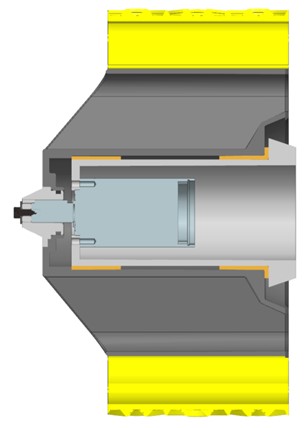

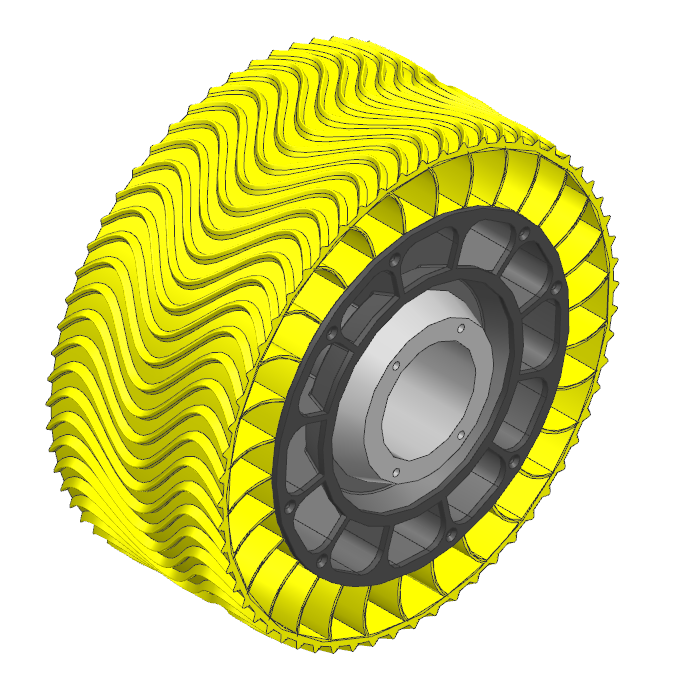

One of the main problems with the Drivetrain of Rover Meyer was the protection against water and dirt. Completely sealing a rotating part can be difficult. The goal was to design the motor and bearing area to be protected against water intrusion. Water can also introduce dirt into the system and damage it.

The plain bearings were pressed into the 3D-printed rim. They slide over an aluminum bushing that was hard anodized to be more resistant to damage.

To prevent lateral slippage, a thread was cut into the Maxon motors. A screw was thus used to prevent lateral slippage. By loosening the screw, it is possible to remove the wheel in a few seconds.

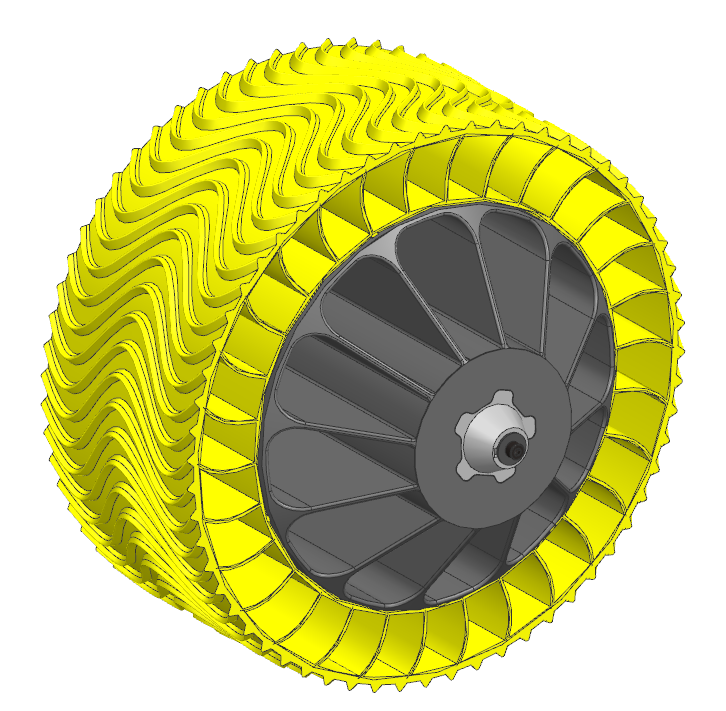

A conical geometry at the rear end of the wheels allows water to drain off, along with dirt. At the front, a closed system with sealing ring protects against dirt and water.

We would like to thank again our engine sponsor Maxon. Maxon not only supported us with the engines, they were also a guest at the first Rover-Träff and showed an exciting presentation about their space section.

Can you share more details about this design. It will be better if you share research paper