Explosion-Reactor

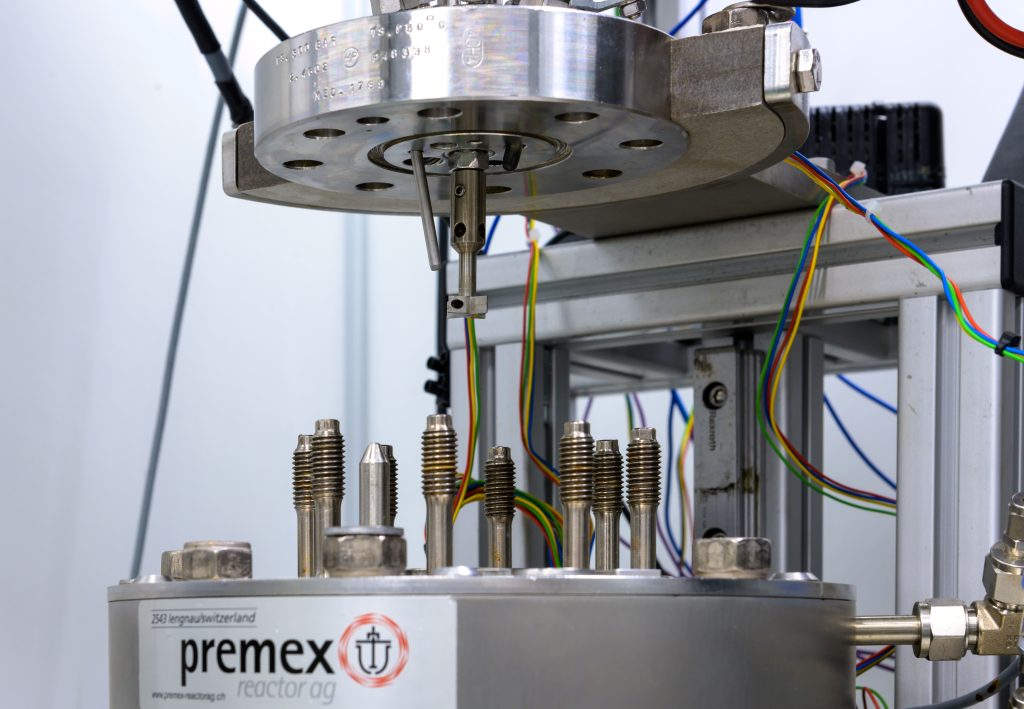

Located on three floors in the PTC, our chemical pilot plant provides companies with an ideal testing environment. Specifically, for assessing the thermal process safety of explosive reactions, we have an explosion reactor at your disposal.

Application example: Chan-Lam coupling

The study conducted with Syngenta Crop Protection AG demonstrated the suitability and safe operation of the «Loop-Reactor,» developed at FHNW-HLS, for process development involving reactions with explosive gas atmospheres, using the copper-catalyzed Chan-Lam coupling of p-toluenesulfonic acid with pyrazole and pure oxygen as an oxidizing agent. Preliminary experiments were conducted with the «explosion reactor» allowing real-time assessment of gas-phase flammability and measurement of maximum explosion pressure. A risk analysis for the «Loop-Reactor» was based on the self-generated safety data, ensuring that desinged pressures for all components matched the maximum expected explosion pressure, determined both theoretically and experimentally in the «explosion reactor». This scale-up methodology, validated by nearly identical oxygen consumption profiles and no significant differences in yield or conversion in both reactors, lays the foundation for future projects.