Hydrogenation

Siegfried AG and FHNW-HLS are together developing a scale-up strategy which aims to achieve a safer, more direct and controlled introduction of hydrogenation reaction processes into production-scale.

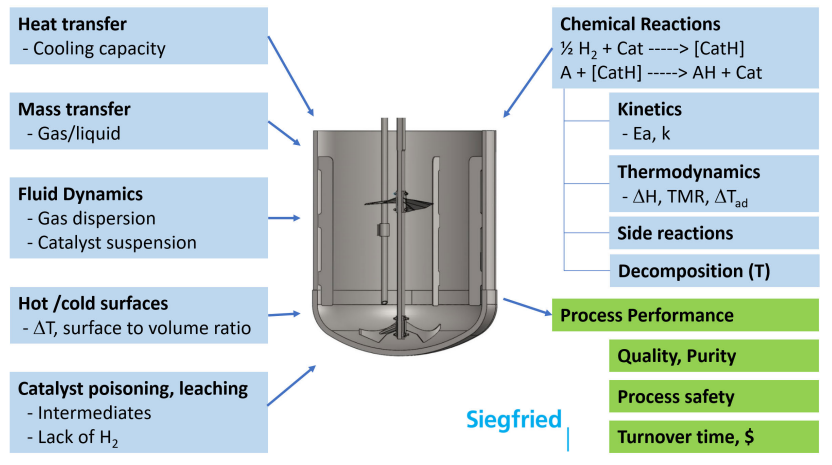

Hydrogenation reactions are very demanding in terms of process safety and chemistry. Main parameters influencing hydrogenation processes are illustrated in blue. With the proposed scale-up strategy, adequate process performance (green) should be achieved with only a few laboratory-scale experiments. This strategy could have a wide field of application since many complex multi-step syntheses have at least one hydrogenation step.

One of the main challenges for scale-up/scale-down is the scale-dependent heat transfer behavior of reactors of different sizes and geometry. While volume and mass increase with a cubic dependency relative to the vessel diameter, the surface area for heat transfer exhibits only a squared dependency. Consequently, the heating/cooling capacity of laboratory reactors is considerably higher than that of reactors at the plant scale, indicating that kinetic effects or degradation on hot/cold vessel surfaces cannot be replicated and examined at the laboratory

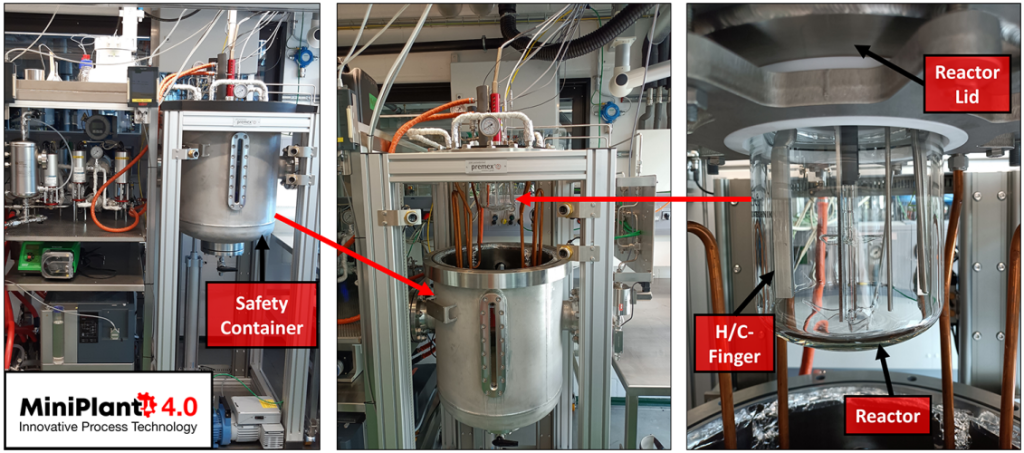

scale. These effects may have a significant impact on process safety, product quality, or the yield of the process especially when impurity deposition and fouling occur, which reduce the heat transfer. Moreover, heterogeneous reactions in general are a challenge for scale-up because mass transfer, partial dissolution, and shear forces on particles influence the kinetics of the process. The majority of these effects are associated with mixing and stirring. The following case study demonstrates how these primary challenges were addressed for a complex, heterogeneous hydrogenation. On the one hand, we have designed a 1.4 L Scale-Down-Reactor (SDR) of a 4000 L hydrogenator using geometrically similar stirrers, bottom shape, and baffles. This enabled us to simulate stirring effects by changing the stirrer speed, with comparable response on mixing, dispersion, mass transfer, and shear. We overcame the challenge of differing heat exchange surface-to-volume ratios by incorporating a heating/cooling finger (H/C-Finger) with limited surface area in a quasi-adiabatic reactor.

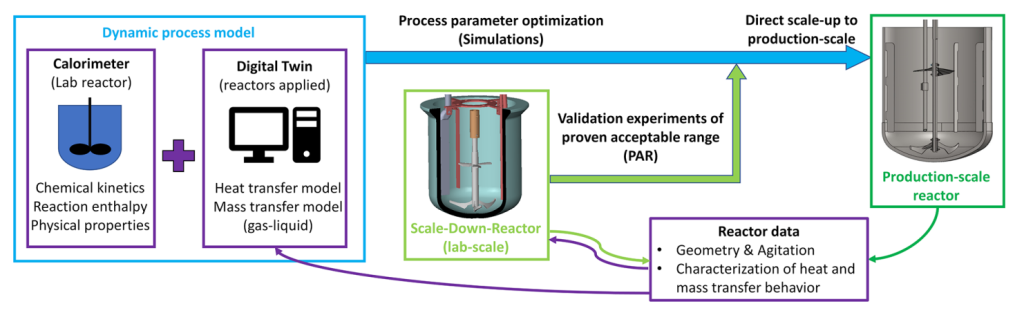

The case study was conducted using an iterative scale-up strategy where information of the large-scale reactor is processed to an in silico reactor model (digital twin). Based on the digital twin and information about the chemical process, a dynamic process model is developed. The model is used to optimize process parameters while simulating the production-scale process. Through laboratory-scale experiments that mimic production-scale conditions, the proven acceptable range (PAR) for those process parameters is subsequently validated. Following this, a direct scale-up to production can occur with high confidence, eliminating the need for intermediate or pilot-scale runs. The information resulting from the production-scale run can be used to iteratively improve the process model and experimental setup.

The results of the project is summarized within the following publications: