Loop-Reactor

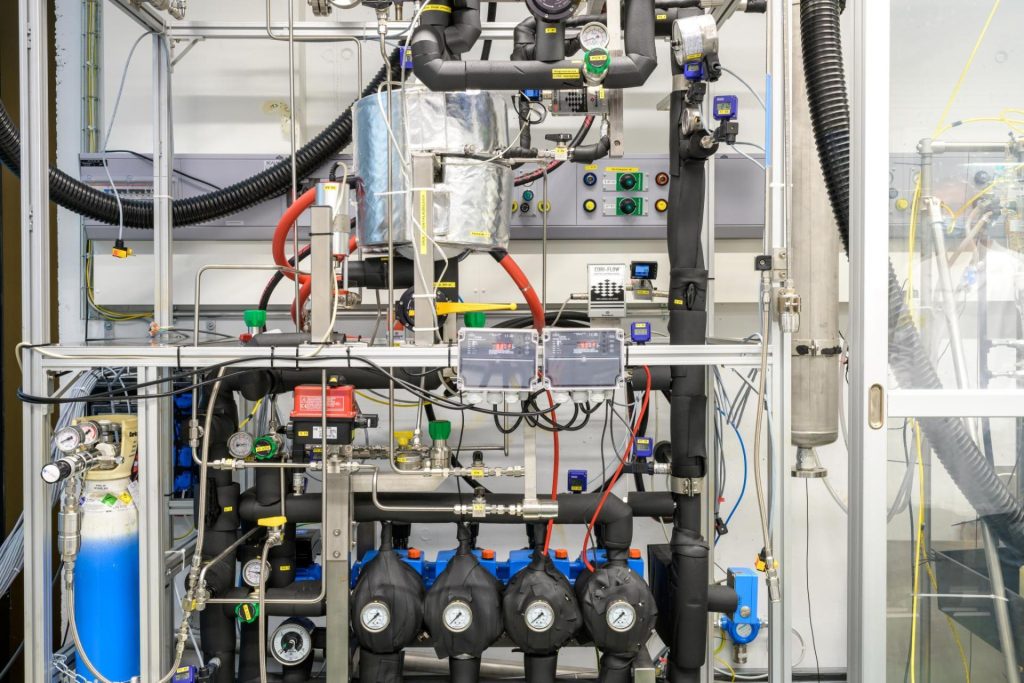

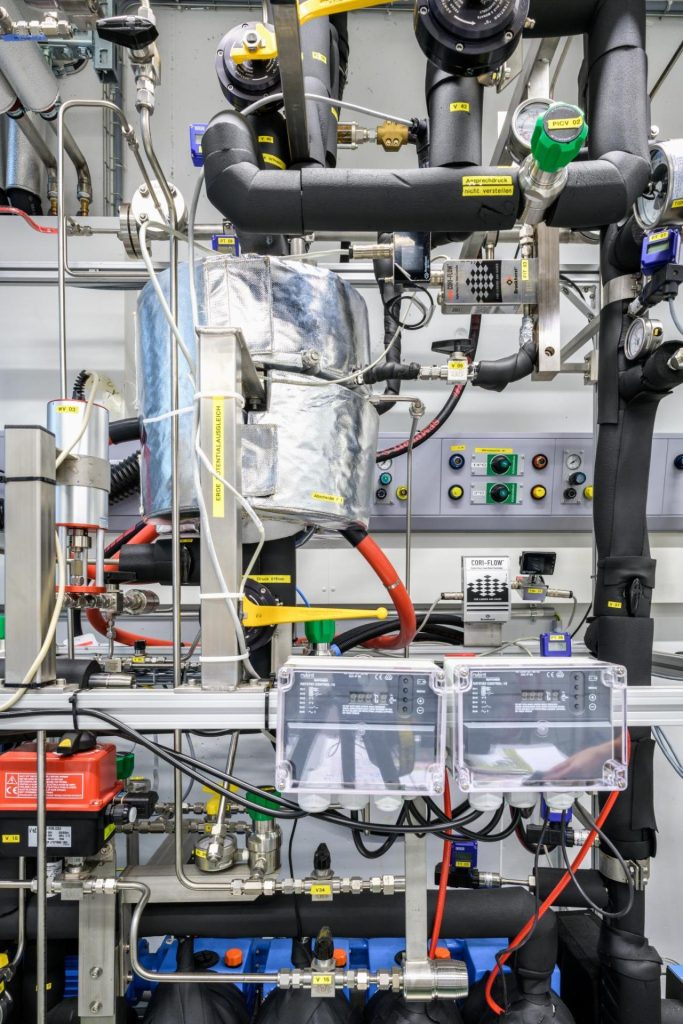

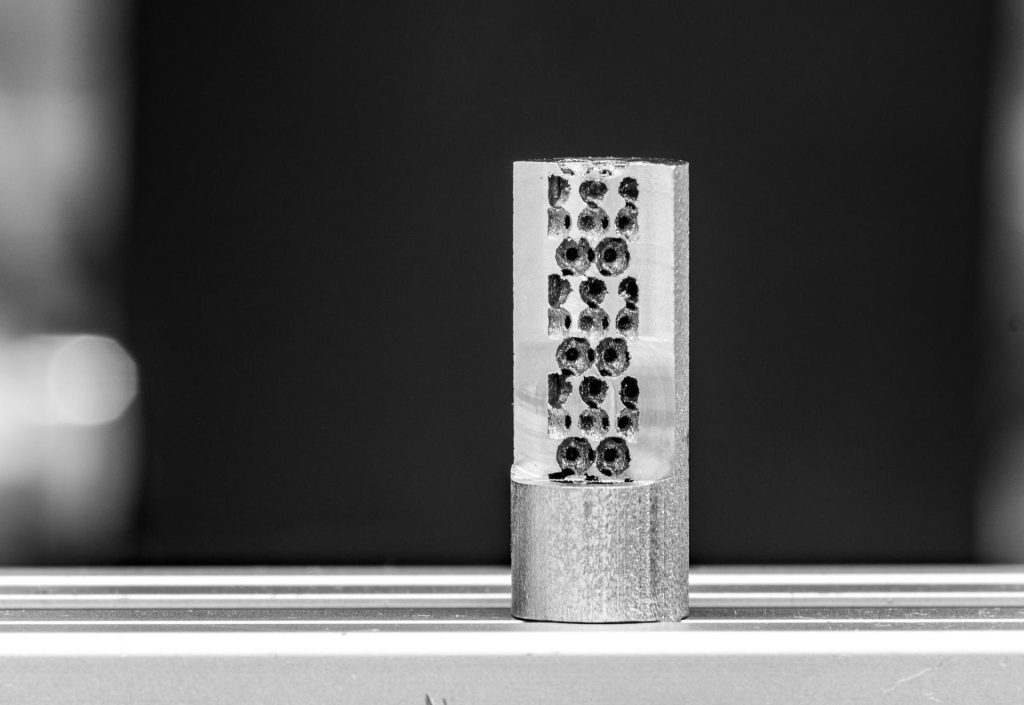

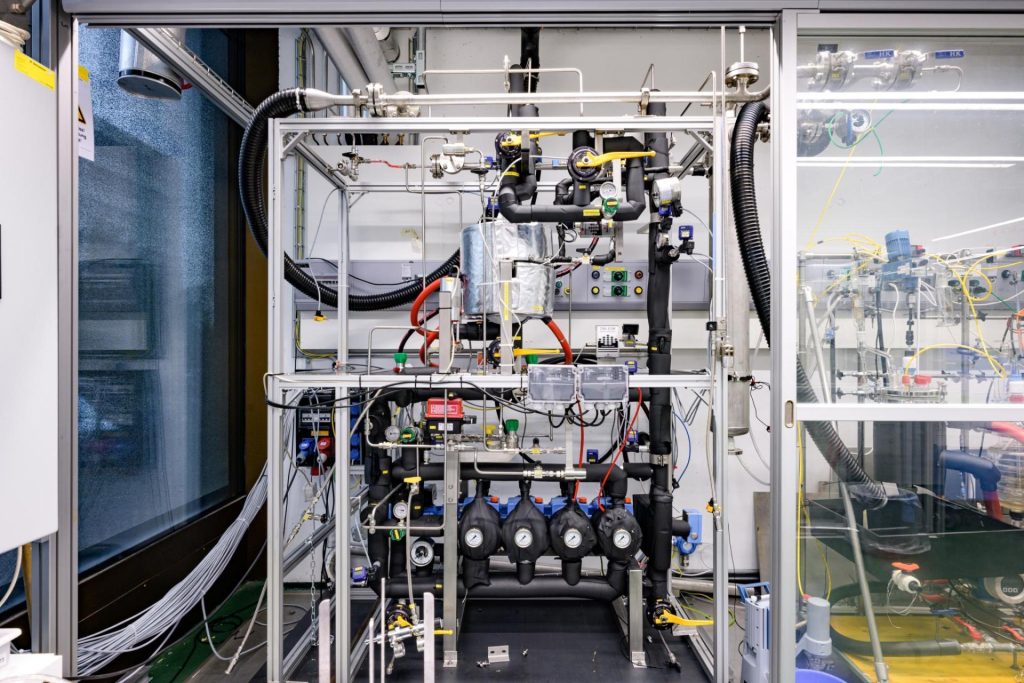

The project between F. Hoffmann-La Roche AG and FHNW-HLS, involved the development of a pilot plant for multiphase reactions using a structured, laser-sintered tube reactor.

The collaboration was motivated and initiated by the current practices in chemical process development within the pharmaceutical industry. Their primary goal is to ensure safe operation during and after scale-up into existing pilot and production facilities through robust reaction control. However, many chemical reactions, such as those involving diazo, azide, and hydrazine chemistry, as well as hydrogenations, phosgenations, nitration, or oxidation with pure oxygen, cannot be inherently performed safely in the currently common multipurpose stirred-tank reactors used in the pharmaceutical industry. As a result, these synthesis routes are either not prioritized for technical production or alternative synthesis routes are sought. Therefore, this work aimed to design a laboratory-scale pilot plant that will enable inherently safe execution of such reactions in the future. This is particularly important for products with limited development time, such as pharmaceutical compounds. Hence, the novel 3D plotted plug-flow reactor, which is built up like an inverse packed-bed reactor, represents an interesting option to other innovative chemical reactors relating to process intensification. This pilot plant unit permits miscellaneous chemical reactions under inherently secure conditions. Heterogeneously catalyzed multiphase reactions with medium to high heat content are in the main focus.