Natural fibre composites for lightweight construction applications

Natural fibre composites are one of the core competences of the Institute of Polymer Technology at the University of Applied Sciences FHNW. Together with BCOMP, the overall performance of these composites was improved.

Extrusion, impregnation, compounding, material modification, overmoulding

Due to their high stiffness and low density, flax fibres are excellently suited for lightweight con-struction. In addition to the advantage of long-term security of supply, the use of renewable raw materials leads to a positive CO2 balance at the end of a product's life cycle.

BCOMP uses both thermoset systems and thermoplastics as matrix materials. Due to the low temperature resistance of the fibres, the choice of thermoplastics is limited to materials with a low melting temperature. The focus of the collaboration with the FHNW was on thermoplastic composites. The duromer-based composites served as a reference.

The Institute of Polymer Technology FHNW worked on optimising the matrix system by using special additives for the natural fibre systems, increasing the degree of impregnation of the flax fibres and the fibre-matrix adhesion and thus improving the overall performance of the compo-site material. For this purpose, a new efficient manufacturing process had to be developed, which enables the continuous production of powerRibs® on a km scale.

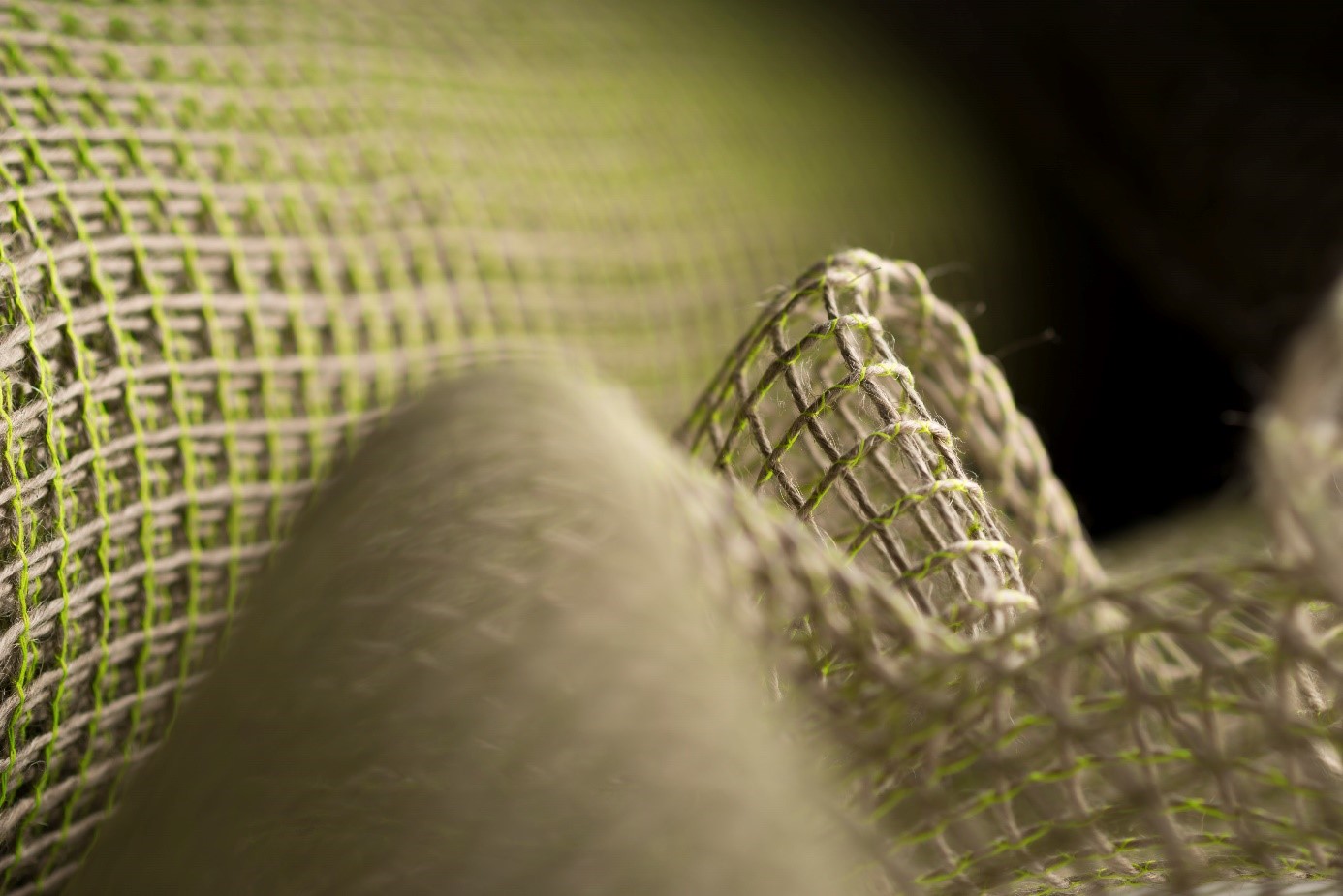

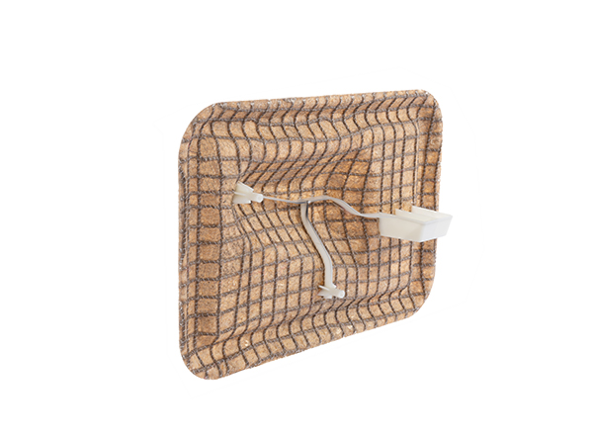

The powerRibs® developed by Bcomp represent a revolution in the "composite world" due to their grid-like structure. Impregnated flax yarns create a ribbing which not only leads to a higher specific stiffness but also to improved damping properties of the component. The potential range of applications for this technology spans many areas and in the meantime the project results have been used to industrialise the material formulation and manufacturing technology. For example, car seats are manufactured with amplitexTM panels that are stiffened on the back with powerRibs®. This not only saves weight and makes cars more ecological, but also significantly reduces vibrations and better absorbs energy in the event of an accident.

Client | BCOMP Ltd |

Execution | |

Duration | 2 years |

Funding | |

Team | Prof. Dr. Christian Rytka, David Botor, Moritz Thommen, Kunal Masania, Jesus Maldonado, Clemens Dransfeld, Julien Rion |