Materials science

Examination of materials and components regarding structure and composition, production process and operation.

Examination possibilities at the Materials Testing Laboratory

Macroscopic photographs and sample preparation

Macroscopic photographs

- Creation of macroscopic detailed photographs of your samples and components with a specific focus on potentially defective areas

- Identification of macroscopic faults and damaged points

- Documentation of the disassembly and evaluation strategy for samples and components

- Use of a standard digital camera, image background blue or white

Sample preparation

- Processing of all common metallic materials on an Fe, Cu, Al, Zn or Ni basis

- If applicable, macro photographs are taken of the areas concerned

- Disassembly of the component and separation of samples.

- Embedding of samples (hot or cold, Ø 40mm).

- Sample preparation by grinding and polishing, or electrolytic polishing

- Chemical treatment of the sample surface by etching

Light microscopy

- Creation of structural images for material and damage analysis

- Examination of matrix structures, casting phases, and secondary and tertiary depositions

- Digital image analysis to determine the proportion of individual structural constituents, their morphological analysis, etc.

- Equipment: ZEISS incident light microscope, KEYENCE digital microscope, IMS and Zeiss image processing and analysis software

Scanning electron microscopy (SEM), EDX measurement

- Imaging of structure under particularly high magnification

- Visualisation of topography effects on a sample

- 3D measurement of sample with digital analysis; optical roughness determination

- Qualitative determination of the composition of a sample using energy-dispersive X-ray (EDX)

- Equipment: SEM Tescan VEGA3 with Bruker EDX

Differential thermal analysis (DTA)

- Taking representative material samples

- Heating / cooling the sample to record energy flows

- Creation of temperature profiles

- Indication of transformation temperatures and linking with material-specific reactions

- Recipes for targeted heating and cooling, e.g. for heat treatments or other annealing processes

- Equipment: DTA 703 from the company BÄHRalyse

Thermal analyses

Temperature measurements

- Instrumenting tests for temperature measurement

- Measured value acquisition (ALMEMO or LabView)

- Evaluation of temperature curves and their analysis

Deriving the heat transfer coefficients from measurement curves

Determination of thermal conductivity

Thermal analysis

- Recording cooling curves from melting

- Identifying conversion points

- Analysing structural quality using measured values, in combination with metallographic specimens

- Equipment: Thermal analysis system from the company OCC

Mechanical testing of materials

Hardness test

- Sample preparation: Exposure of areas to be examined and preparation of the surface

- Testing on at least three representative points

- If applicable, selection of areas for further examinations (metallography)

- Testing method in accordance with Vickers, Brinell and Rockwell

- Equipment: GNEHM hardness testing machine, micro hardness test

Tensile testing

- Processing of standardised test geometries

- Tensile tests indicating the test parameters strain rate and traverse speed

- Determination of the static strength (Rm, RP0,2) of the e-module, as well as stretch

- Equipment: ZWICK tensile testing machine 100 kN

Spark emission spectroscopy

- Quantitative analysis of the composition of a metallic material

- Aluminium, iron and copper standard

- Brand / type: SPECTRO / SPECTROLAB

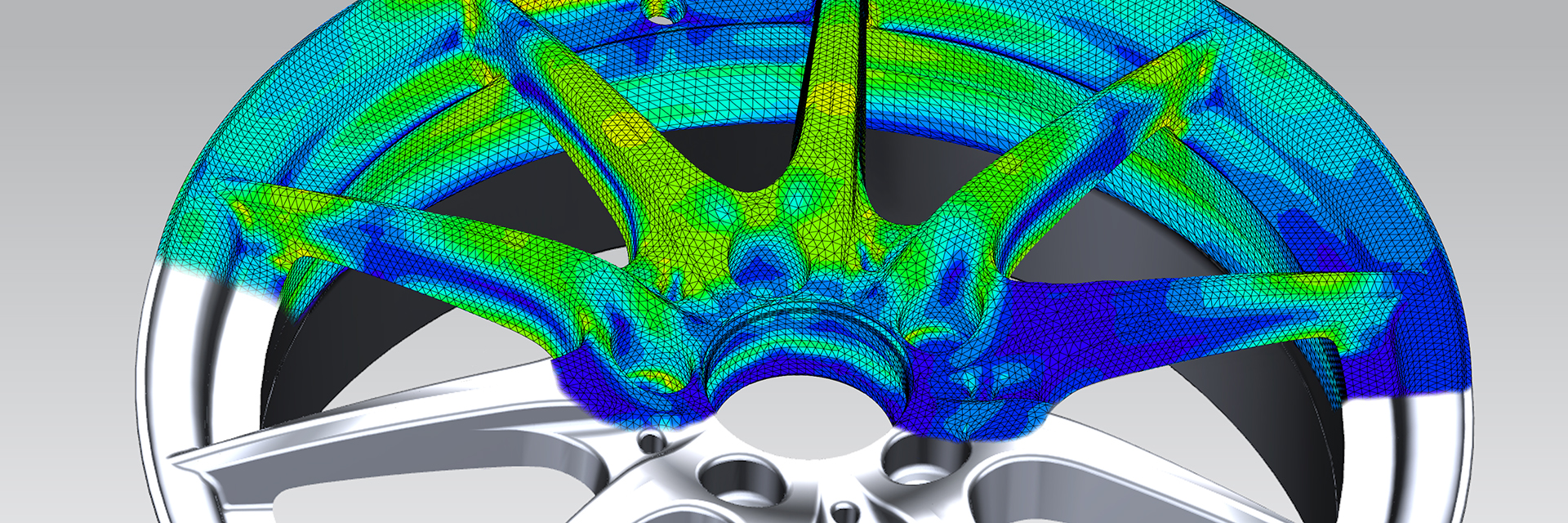

Process simulation

- DEFORM to simulate deformation processes in metals (2D and 3D)

- MAGMASoft for simulating mould-filling and solidification in casting processes

Analysis of the results

- The process for analysis and the subsequent report is discussed in detail at the beginning

- The results are delivered either in report form or as individual results of each examination, as you wish

- If you require a report is selected, the examination results are supported by sound foundations

We would be happy to examine your question and develop possible solutions on the path to process and material optimisation, damage analysis, and the development of new products or manufacturing methods.

Contact

Loading